Biogas cogeneration

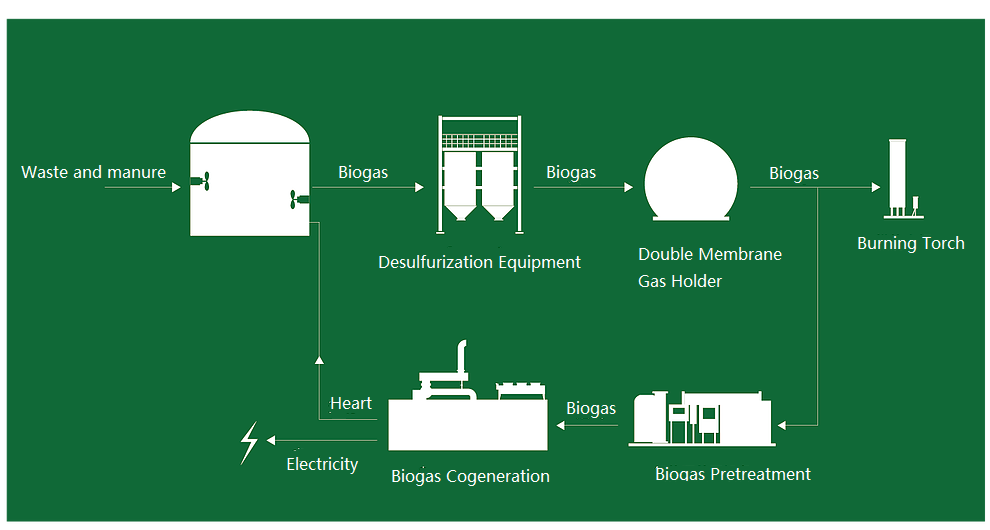

The PowerLink biogas co-generation unit uses renewable energy biogas as the input fuel to generate clean energy: electricity and heat, and the comprehensive utilisation rate of energy exceeds 82%. It involves a low investment costs, short recycling cycles, and cost-effective features- saves the customer more than 70% in energy costs while reducing CO2 emissions by 50%.

The generated electricity is supplied to the local power facility, and the remaining electrical energy is sold to the grid; the generated thermal energy is supplied to the anaerobic fermentation system for insulation or as domestic hot water. PowerLink's co-generation distributed energy products guarantee the efficiency and independence of energy use.

The main application areas are in the field of industrial organic wastewater, agricultural straw, livestock farming farms, and urban landfills.

PowerLink provides advanced, integrated gas pre-treatment equipment for desulphurisation, cold drying/de-humidification, and pressurisation of biogas to ensure that biogas meets the co-generation conditions.

PowerLink offers three types of co-generation units: indoor, silent and outdoor, to meet different application environments:

-

Open unit for indoor use;

-

Open unit + silent box for indoor or outdoor (need to prevent rain) with a low noise level;

-

Open unit + container body for any outdoor environment with low noise.

High overall efficiency

The electrical efficiency is at 36%~44%, with the thermal efficiency at 45%~48%, which makes the comprehensive efficiency is over 85%, the economic benefit is obvious as to the short payback period from the investment.

Strong and sturdy

The box body is made out of high-strength container weather-resistant steel plate. The surface is sprayed according to the sea environment and it has a strong corrosion resistance facility. At the same time,all pipes are made of stainless steel to ensure durability in the biogas environment.

Flexible grid-connected control technology

The advanced intelligent control system can simultaneously monitor other main and auxiliary equipment in the biogas project to make the operation to be more safe and reliable. The technology allows the unit to be connected to the city-grid, which meansthere will be three ways to provide energy output: self-use / surplus power / and transfers to the grid, to meet different application needs.

Short construction period

Both the power output system and the thermal energy output system are of modular in design, plug and play feature, and can be quickly installed and put into use.

Efficient waste heat recovery system

Modular heat exchange components are used to fully utilise the high-temperature cylinder heat water jacket and high-temperature exhaust heat generated by the engine, and are converted into heat energy through high-efficiency heat exchanger, waste heat boilers and other equipment, and the thermal efficiency exceeds 45%.

Continuous running time

The outdoor unit is equipped with automatic oil filling device and new/old oil tank to provide automatic oil re-fill and oil discharge, ensuring long-term continuous operation,reducing labour related costs.

For more information related to gas products, please visit our gas website.